Project Brief

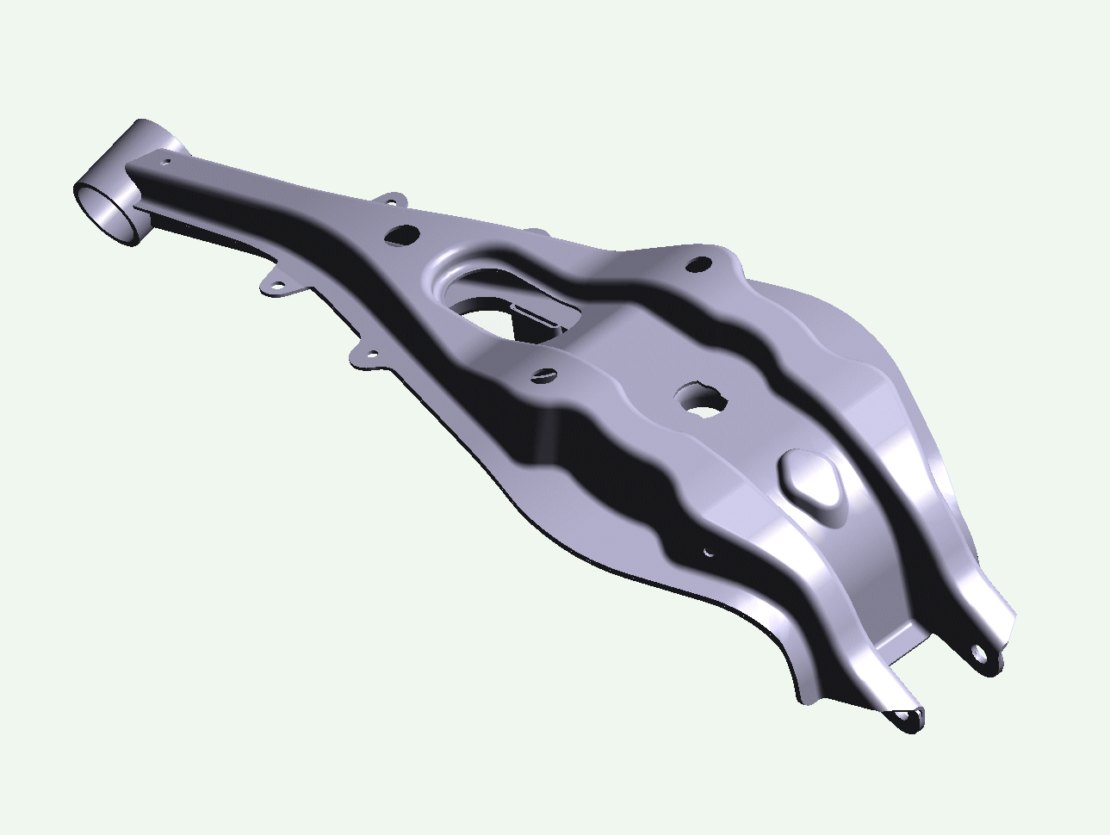

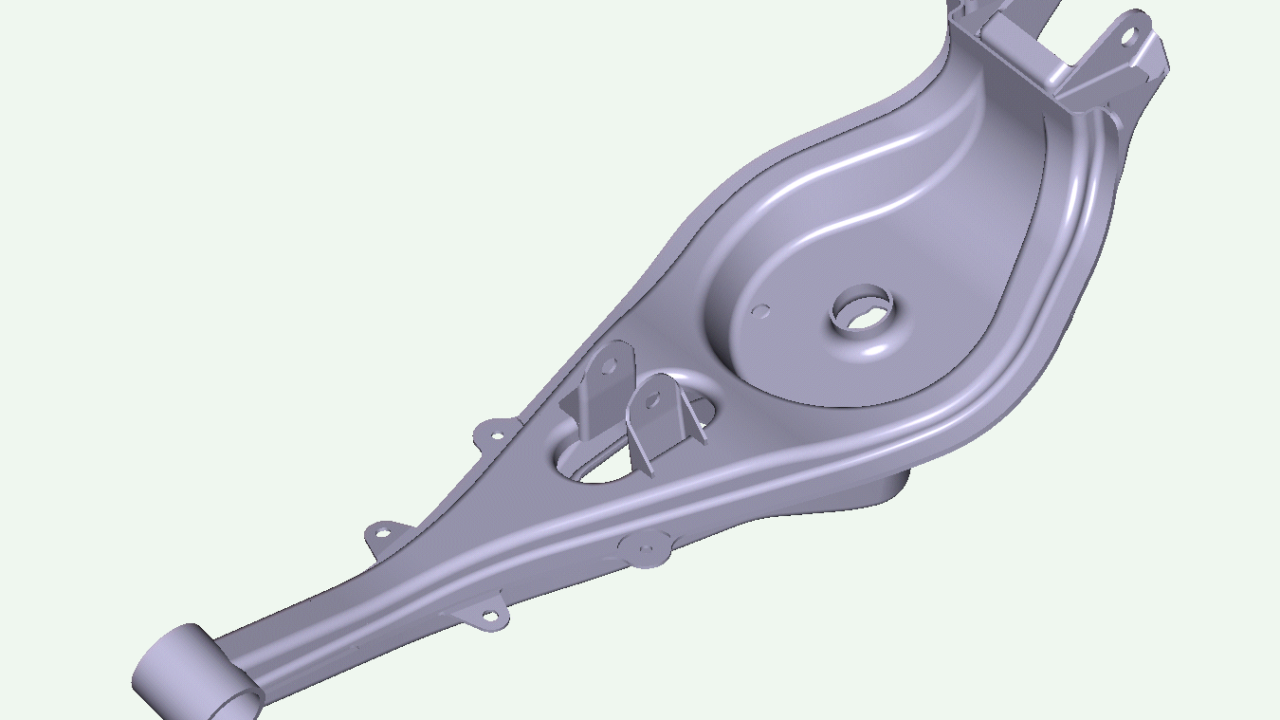

ECP, a first tier supplier to Rover Group, had been tasked to replace the original cast aluminium arm with a pressed steel alternative. Randle Engineering were brought into the project to produce concepts for evaluation, and a complete design and analysis program.

Project Summary

The original cast aluminium suspension arm was not reaching its fatigue life and so submissions for a redesign were sought. A close co-operation between MG Rover, ECP, Chasestead (the prototype manufacturers) and Randle Engineering proved the winning submission against several supplier and in-house designs.

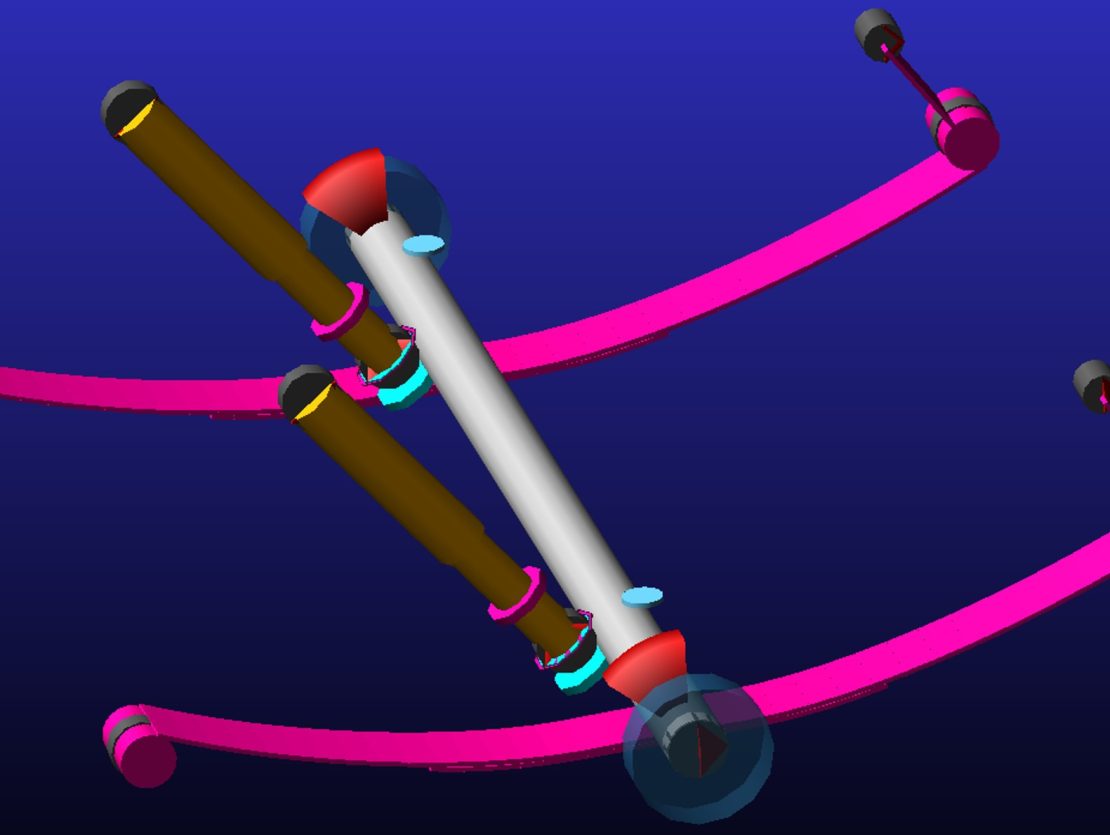

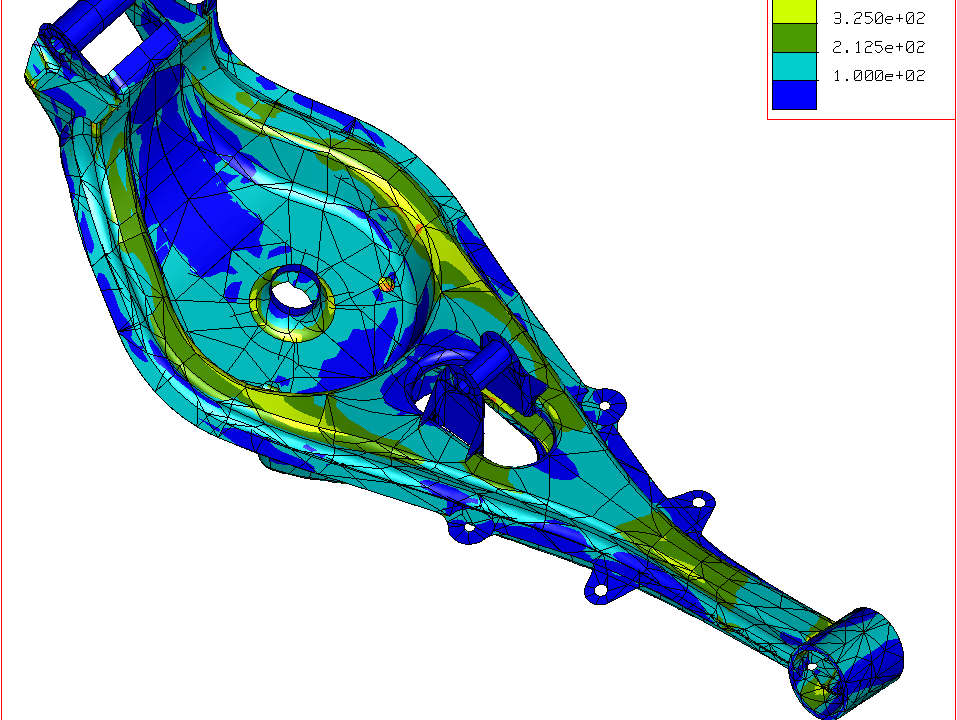

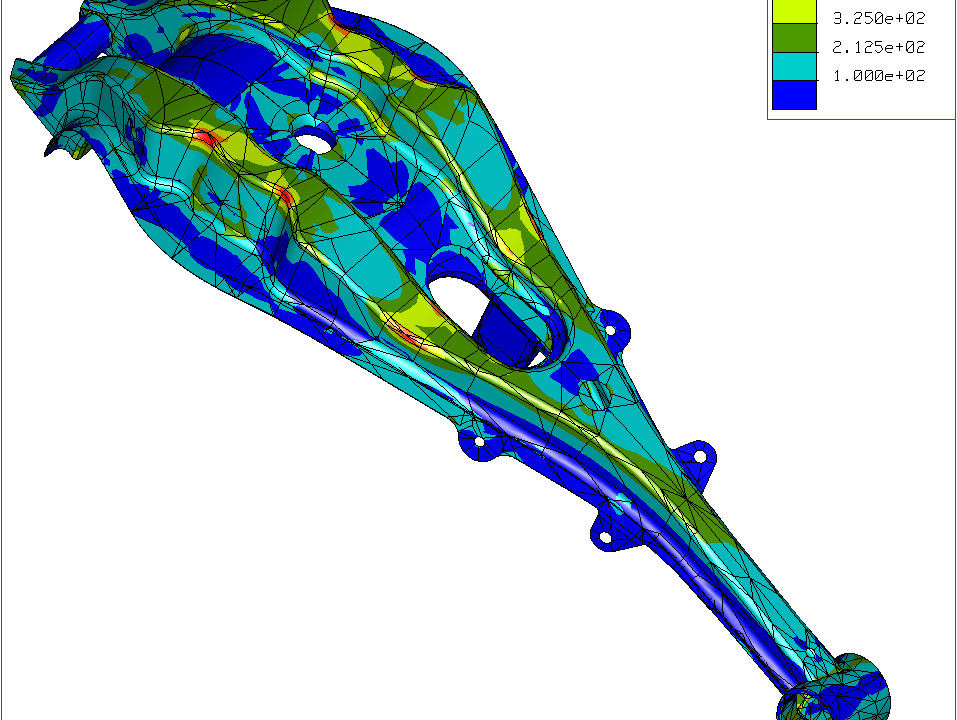

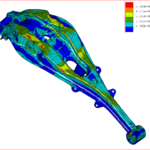

Randle Engineering developed a two piece pressed steel alternative and completed the required structural analyses in-house, including both abuse & fatigue loadcases. The new component fits in the original package space and delivers improved strength & stiffness at a reduced price.

Project Outcomes

Successful design ready for production: 70% improvement in stress & fatigue criteria, 350% improvement in stiffness, reduced assembly time, 50% cost saving

Capabilities

Let’s work together

If you think our capabilities and experience could add value to your project, please get in touch to discuss it with our team.