Project Brief

Bentley Motors commissioned Randle Engineering to develop concept proposals for a mounting system to improve the noise isolation properties of the Bentley Arnage driveline, and to eliminate the driveline shunt resulting from a new high-torque power unit.

Project Summary

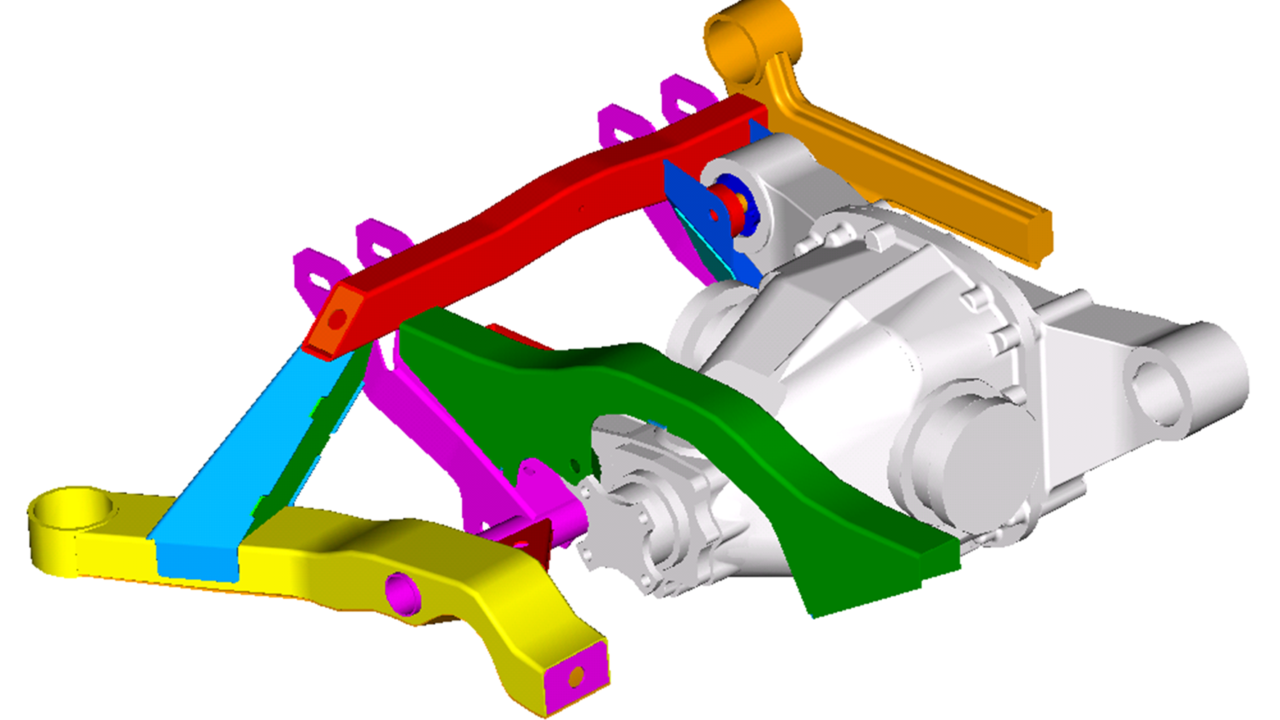

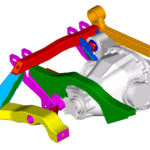

The introduction of a new higher torque powertrain to the Arnage meant that the final drive unit and rear subframe had be re-engineered to accommodate the additional loads whilst delivering the exceptional refinement expected by Bentley customers.

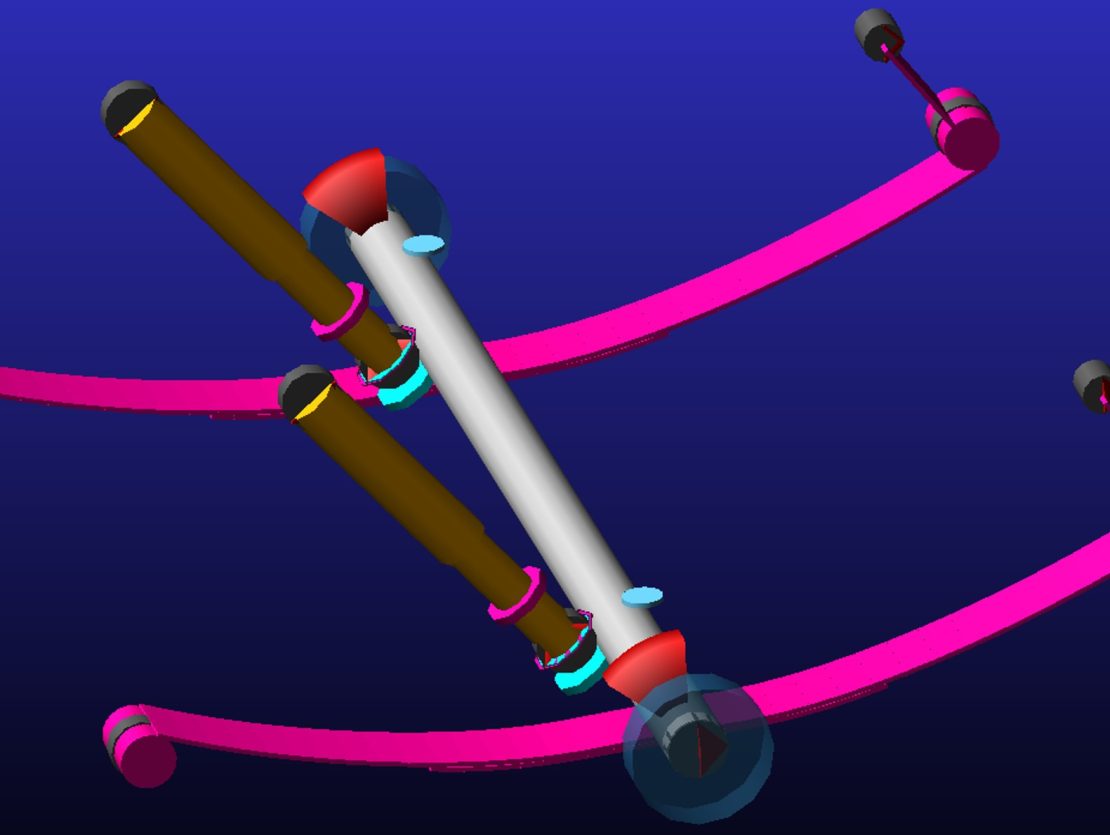

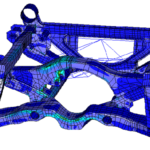

To achieve the targets Randle Engineering devised a novel mounting system concept for the final drive unit and conducted the required simulation activities to confirm its improved performance. This included dynamic simulations and a comprehensive modal analysis.

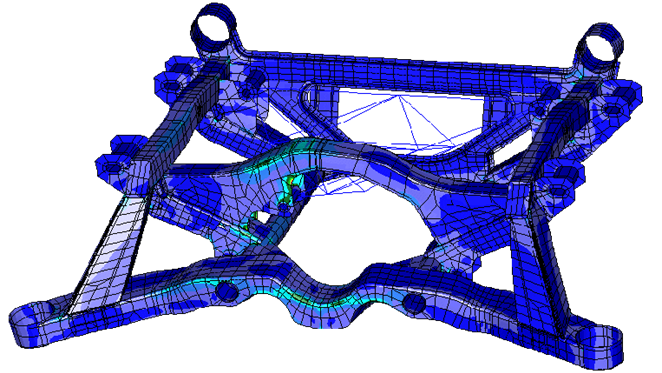

Following the success of this concept Randle Engineering were awarded the contract to production engineer the final solution. The concept was turned into reality with detailed design activities and structural analyses completed on both the final drive casing and rear subframe.

This project was turned around in the 9 months available with all targets achieved.

Project Outcomes

Successful re-design of final drive mounting and subframe to eliminate driveline shunt and reduce noise by up to 6bB.

Capabilities

Let’s work together

If you think our capabilities and experience could add value to your project, please get in touch to discuss it with our team.